Shot blasting machine Poland

Roller conveyor shot blasting machines optimize I-Beam/H-Beam surface preparation, boosting coating adhesion and structural integrity for construction and industrial projects, like bridges, skyscrapers, and heavy machinery. Pre-Engineered Buildings (PEB) leverage precision-engineered shotblating I/H-Beams for cost-effective, durable solutions in warehouses, commercial structures, and agricultural facilities, delivering scalable frameworks with minimal lead-time.

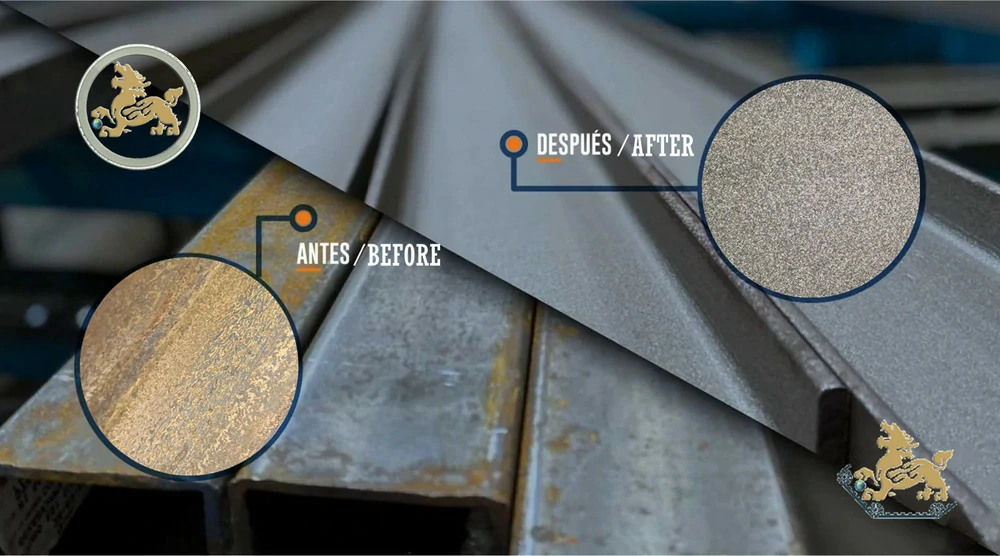

To ensure long-term durability, all components undergo SA 2.5 (SSPC SP-10) surface preparation—a near-white metal blast cleaning standard—achieving a 60-75μm profile depth. This rigorous process:

The shot blasting design speed with 1m/minute;

The shot turbines with 8 * 11kw;

Total blasting capacity is 8* 180 kgs/minute;

Surface standard Sa 2.5 (SSPC sp-10),60-75μm;