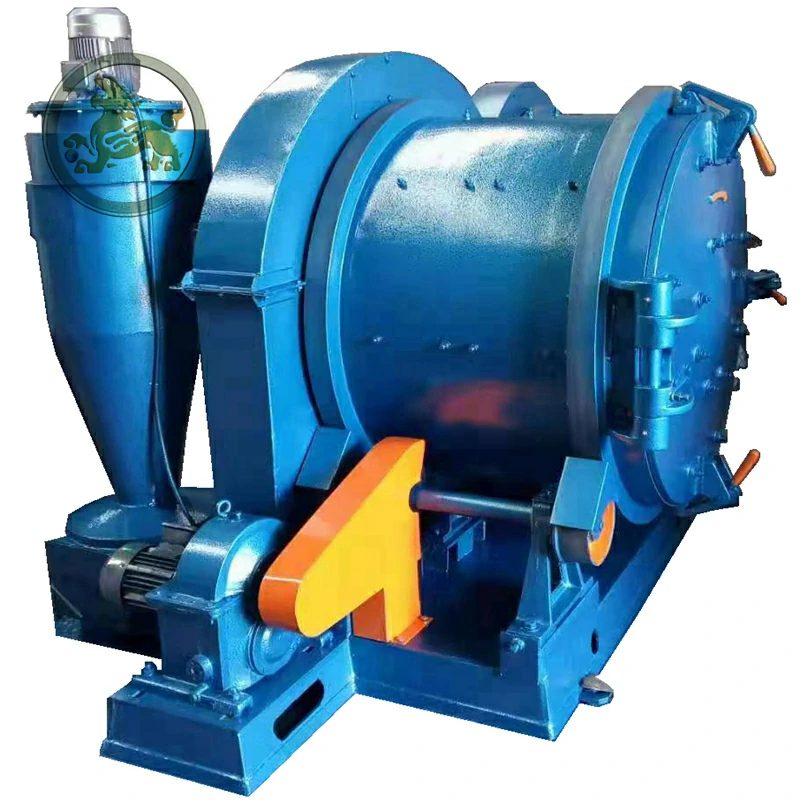

Barrel type shot blasting machine for Foundry

A drum type shot blasting machine for foundry, aka, barrel shot blasting machine, is a specialized piece of equipment used in the metal casting and foundry industries to clean and prepare the surface of cast components. This machine uses centrifugal force to propel small steel spheres, known as “shot abrasive,” at high speeds to remove contaminants, scale, and surface imperfections on the castings. The drum design allows for efficient and continuous processing of large quantities of small-to-medium-sized components.

Barrel type shot blasting machines for foundry is a critical piece of equipment for cleaning and preparing cast components, ensuring a consistent finish and improved quality. Its rotating drum design, shot propulsion system, and integrated abrasive recovery and dust extraction features make it an efficient and versatile choice for foundries and metal casting operations.

The category of the foundry:

Foundries typically specialize in casting specific types of metal, such as iron, steel, aluminum, copper, or brass. The products produced by foundries include a wide variety of metal parts and components, ranging from small and simple to large and complex, which are used in various industries such as automotive, aerospace, construction, and more.

1. General Foundry Industry

2. Steel Foundry Industry

3. Non-Ferrous Foundry Industry

4. Investment Casting Industry

5. Die Casting Industry

Key benefits of using a Barrel type shot blasting machine for the foundry:

Barrel type shot blasting machines can process large quantities of foundry parts quickly and efficiently, improving productivity.

The blasting process removes contaminants and impurities from surfaces, resulting in a cleaner, smoother finish.

Regular use of barrel-type shot blasting machines can help to extend the lifespan of foundry equipment by removing corrosion and wear.

The use of automated barrel type shot blasting machines can reduce the need for manual labor, saving time and money.

The use of environmentally-friendly blasting media, such as steel shot or grit, can help to reduce waste and minimize environmental impact.

FAQ of Barrel type shot blasting machine for the foundry:

A barrel type shot blasting machine is a type of industrial shot blaster used for surface preparation, typically in the foundry industry. It consists of a rotating barrel or drum that is filled with abrasive media, such as steel shot or grit. The parts to be cleaned or prepared are loaded into the barrel, which is then rotated while the abrasive media is propelled at high speed against the surface of the parts. This process removes contaminants, rust, scale, and other impurities from the surfaces of the parts, leaving them clean and ready for further processing or finishing. Barrel shot blasting machines are often used for cleaning and preparing large quantities of parts and are designed for high-volume production.

Here are some key features of this type of shot blasting machine:

Drum design: The machine features a rotating drum or barrel, where the cast components are loaded. As the drum rotates, the parts tumble and mix, ensuring even exposure to the shot blast.

Shot propulsion: The machine uses a wheel or impeller mechanism to propel the shot at high velocity towards the cast components. The speed and direction of the shot can be controlled to ensure effective cleaning of the parts.

Abrasive recovery and recycling: A built-in system recovers the used shot, separates it from dust and debris, and recycles it for reuse. This improves the efficiency and sustainability of the process.

Dust extraction: An integrated dust collection system helps maintain air quality and worker safety by removing dust and fine particles generated during the shot blasting process.

Versatility: Drum type shot blasting machines can handle a wide range of component sizes and shapes, making them well-suited for various foundry applications.

Process automation: The machines often feature automated loading and unloading systems, reducing manual labor and improving overall efficiency.

Refer to this guideline chart of the wheelabrator buying a shot blasting machine. Check it and compare it with your sourcing budget, but please bear in mind that the cost of the shot blasting machine is just for your information, the different purpose and workload needs the shot blasting machine’s shot wheels, motor, quantity, brand, automated level all different, so the final cost please contact us for confirm;

Here are five key benefits of using a shot blasting turbine:

- Efficient surface preparation: Shot blasting turbines are highly efficient in removing surface contaminants and preparing surfaces for subsequent processing operations. They are capable of removing rust, scale, paint, and other impurities from a variety of surfaces, including metal, concrete, and stone.

- Consistent results: Shot blasting turbines provide consistent results, ensuring that surfaces are thoroughly cleaned and prepared to the desired level of finish. This helps to ensure that subsequent coatings and finishes adhere properly and last longer.

- Versatile: Shot blasting turbines can be used for a wide range of applications, including surface preparation, cleaning, and deburring. They can be used on a variety of surfaces and materials, making them a versatile tool for many industries.

- Environmentally friendly: Shot blasting turbines can be used with a variety of blasting media, including steel shot, glass beads, and plastic media. This allows for the use of environmentally friendly blasting media, reducing the impact of the blasting process on the environment.

- Cost-effective: Shot blasting turbines are a cost-effective solution for surface preparation and cleaning, offering a high return on investment due to their efficiency and durability. They can be used in a variety of applications, reducing the need for multiple machines and equipment, further reducing costs.

The shot blasting machine market for foundry is a growing industry, driven by increasing demand for high-quality castings with improved surface finish, durability, and strength. Shot blasting machines are used in foundries for cleaning, descaling, and surface preparation of castings before further processing such as painting or coating.