Hanger type shot blasting machine for Foundry

The hanger type shot blasting machine is a versatile and efficient surface treatment solution, specifically designed for the foundry industry. It is used to clean, descale, and remove rust from castings, as well as to prepare surfaces for painting or other finishing processes. This hook model shot blasting equipment employs the use of high-speed rotating impeller wheels to propel steel shots or abrasive media at the surface of the workpiece, thereby achieving the desired surface finish.

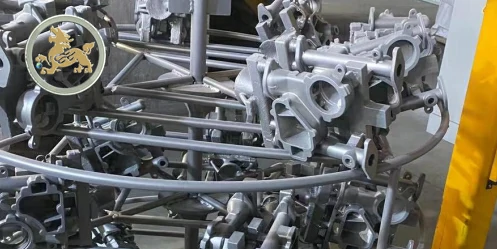

The hanger type shot blasting machine for foundry is an essential piece of equipment for surface preparation and cleaning of castings. Shot blasting machine main components includes a shot blasting cabinet, workpiece hangers, shot blasting wheel turbines, abrasive recycling system, dust collection system, and a control system. This blasting machine offers efficient and uniform cleaning of workpieces, making it an ideal choice for foundry applications.

The category of the foundry:

The foundry industry is generally classified as a part of the manufacturing sector.

Specifically, it is a subcategory of the metal casting industry, which involves the production of metal components by pouring molten metal into a mold and allowing it to solidify.

Foundries typically specialize in casting specific types of metal, such as iron, steel, aluminum, copper, or brass. The products produced by foundries include a wide variety of metal parts and components, ranging from small and simple to large and complex, which are used in various industries such as automotive, aerospace, construction, and more.

Key benefits of using a hanger type shot blasting machine for the foundry:

The shot blasting machine is highly effective in removing surface contaminants such as rust, scale, and other impurities from metal castings. This results in a smoother and more uniform surface that is better suited for subsequent processing operations.

The shot blasting machine can process multiple castings simultaneously, which helps to increase production rates and reduce the overall processing time. The use of an overhead conveyor system also allows for efficient material handling, further improving productivity.

The shot blasting machine is designed to be durable and low-maintenance, which helps to reduce the overall maintenance costs and downtime associated with equipment repair and replacement.

The hanger type shot blasting machine is equipped with a dust collection system that helps to reduce airborne dust and particles, improving the working environment and protecting the operators from respiratory hazards. The use of an overhead conveyor system also helps to reduce the risk of worker injury associated with manual material handling.

The shot blasting machine is a cost-effective solution for surface preparation and cleaning of metal castings, offering a high return on investment due to its efficiency and durability. Additionally, the ability to recycle spent abrasive particles and debris helps to reduce waste and disposal costs.

FAQ of hanger type shot blasting machine for the foundry:

Refer to this guideline chart of the wheelabrator buying a shot blasting machine. Check it and compare it with your sourcing budget, but please bear in mind that the cost of the shot blasting machine is just for your information, the different purpose and workload needs the shot blasting machine’s shot wheels, motor, quantity, brand, automated level all different, so the final cost please contact us for confirm;

Here’s a description of the main components and features of a hanger type shot blasting machine for foundry:

- Shot blasting Cabinet:The cabinet is the main enclosure that houses all the essential components, such as the workpiece hangers, blasting wheels, and abrasive recycling system. It is made of heavy-duty steel plates, lined with wear-resistant materials to withstand the abrasive action of the shot blasting process.

- Workpiece Hangers:These are specially designed hooks or fixtures that hold the workpieces inside the blasting cabinet. The hangers can be rotated, providing 360-degree coverage to ensure uniform cleaning of the entire workpiece. The hanger system can be manual or fully automated, with programmable logic controllers (PLCs) managing the cleaning process.

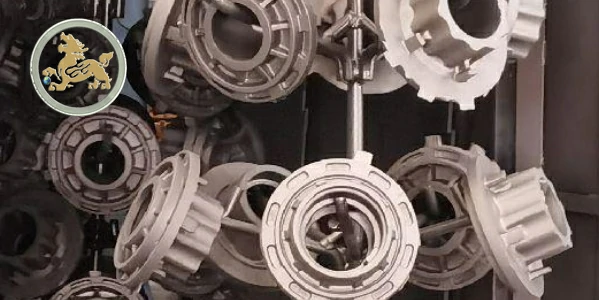

- Blasting Wheels:Also known as impeller wheels or turbines, these are the core components of the shot blasting machine. They are responsible for accelerating the abrasive media and projecting it onto the workpiece surface. The number and power of the blasting wheels may vary depending on the size and production requirements of the foundry.

- Abrasive Recycling System:This system is responsible for collecting, cleaning, and recycling the abrasive media after it has been used in the shot blasting process. It typically consists of a screw conveyor, bucket elevator, separator, and storage hopper. The recycling system helps reduce operational costs by minimizing the consumption of abrasive media.

- Dust Collection System:To maintain a clean and safe working environment, a dust collection system is integrated into the shot blasting machine. It extracts dust and fine particles generated during the blasting process, filtering and discharging clean air back into the atmosphere.

- Control System:The control system manages the entire operation of the hanger type shot blasting machine. It can be either a simple electrical panel with basic controls or an advanced PLC-based system that offers more automation and process control options.

Here are five key benefits of using a shot blasting turbine:

- Efficient surface preparation: Shot blasting turbines are highly efficient in removing surface contaminants and preparing surfaces for subsequent processing operations. They are capable of removing rust, scale, paint, and other impurities from a variety of surfaces, including metal, concrete, and stone.

- Consistent results: Shot blasting turbines provide consistent results, ensuring that surfaces are thoroughly cleaned and prepared to the desired level of finish. This helps to ensure that subsequent coatings and finishes adhere properly and last longer.

- Versatile: Shot blasting turbines can be used for a wide range of applications, including surface preparation, cleaning, and deburring. They can be used on a variety of surfaces and materials, making them a versatile tool for many industries.

- Environmentally friendly: Shot blasting turbines can be used with a variety of blasting media, including steel shot, glass beads, and plastic media. This allows for the use of environmentally friendly blasting media, reducing the impact of the blasting process on the environment.

- Cost-effective: Shot blasting turbines are a cost-effective solution for surface preparation and cleaning, offering a high return on investment due to their efficiency and durability. They can be used in a variety of applications, reducing the need for multiple machines and equipment, further reducing costs.

The shot blasting machine market for foundry is a growing industry, driven by increasing demand for high-quality castings with improved surface finish, durability, and strength. Shot blasting machines are used in foundries for cleaning, descaling, and surface preparation of castings before further processing such as painting or coating.