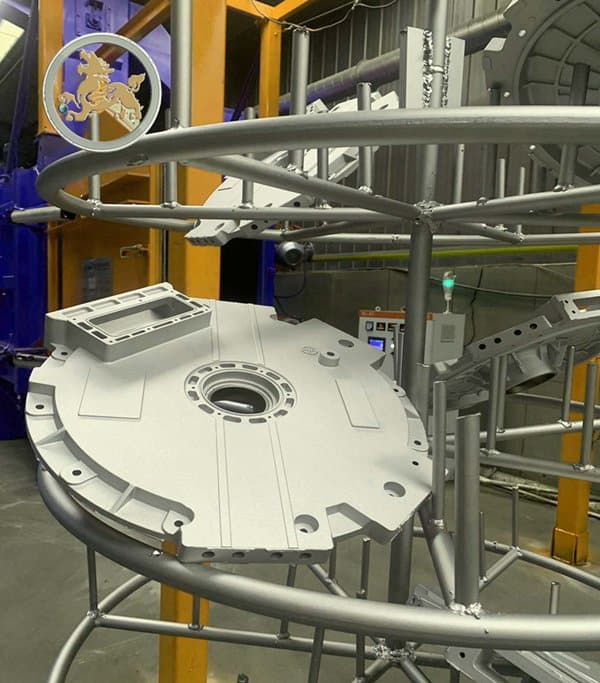

Shot blasting machine Turkey

A shot blasting machine for aluminum die-casting serves a crucial function in the manufacturing process by effectively cleaning, descaling, and finishing aluminum die-cast parts. This machine utilizes high-speed projectiles, such as steel shots or grits, to bombard the surface of the parts. The impact of these projectiles removes impurities, scale, burrs, and other surface irregularities present on the die-cast parts.

By subjecting the parts to this abrasive action, the shot blasting machine not only cleans the surfaces but also improves their texture and prepares them for subsequent processes like coating, painting, or further finishing. The abrasive blasting process enhances the adhesion of coatings and finishes to the aluminum surfaces, ensuring a more durable and aesthetically pleasing end product.

The shot blasting design capacity with 20-40pc/5 minute;

The shot turbines with 2 * 11kw;

Total blasting capacity is 2* 180 kgs/minute;

With VFDs (Variable Frequent Drive);