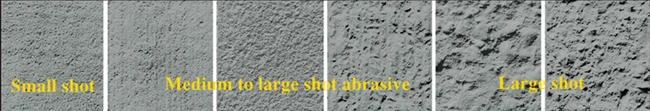

The stone/marble shot blasting machine makes the stone surface have the characteristics of high anti-skid performance, good flatness, and strong 3D stereoscopic effect, which are deeply loved by customers.

The surface by the stone shot blasting machine is roughened. When the bricks are laid on the ground, when it rains or snows, the pavement can be better anti-skid, and the outer wall of the wall makes the stone appear original and more natural.

Shot blasting machine for retexturing stone. Including: marble, artificial stone, granite, curbs, floor tiles, cement tiles, pavement blocks, etc.

Roller type shot blasting machine and mobile road surface shot blasting machine;

The working principle of the stone surface shot blasting machine: The electronically controlled frequency conversion reducer drives the roller table to send the workpiece into the shot blasting chamber. The skin and its dirt change rapidly. The projectile and dust entering the workpiece are transported to the projectile circulation system by the recovery screw, and the workpiece is loaded and unloaded from both sides of the cleaning. Stone surface cleaning shot blasting machine is a kind of high-function continuous operation cleaning, with continuous feeding, stable quality, beautiful appearance, and no blind spots, low cost, high function, large batch processing, energy saving and environmental protection, and durable appearance; but it usually belongs to Large and medium shot blasting equipment cannot be moved.

The road shot blasting machine is a mobile type, working on the surface of the road while moving; it is more used on ordinary roads, highways, airport runways, etc.;

Its advantage is its strong adaptability and ability to work under complex geological conditions; however, it also has disadvantages such as low efficiency and high cost.