Shot Blasting Machine overview of each main parts

Table of Contents

Overall description of the Shot blast machines:

Shot Blasting Machine for sale is rapidly developed according to of modern industries:

Shot blasting is a work process that utilizes centrifugal wheel turbines force with the assistance of high-velocity steel abrasives used for the treatment of metal, stone and wood surfaces.

The shot blasting process aids in obtaining exceptional cleaning for cut, weld, drill, etc. and preparation of the surfaces for the finishing operations of painting, coating, etc.

The system of shot blasting with the centrifugal shot wheel turbine, projectile of the abrasive particles at a very high speed of 75 to 110 m/second by a deflector controlled, has proven to be more productive than by the compressed air, so that can achieve a more effective and better uniform finishing of the surface.

The process of shot blasting machine for sale:

- For cleaning of metals like: ferrous and non-ferrous foundry, steel, forgings, etc.

- For mechanical cleaning of surface for further process: sheets, beam, profiles, etc.

- For shot peening to increase the mechanical properties such as for increasing resistance to fatigue and stress for springs, gears, clutches, etc.

- Preparation of surfaces for following operations like painting, coating, etc.

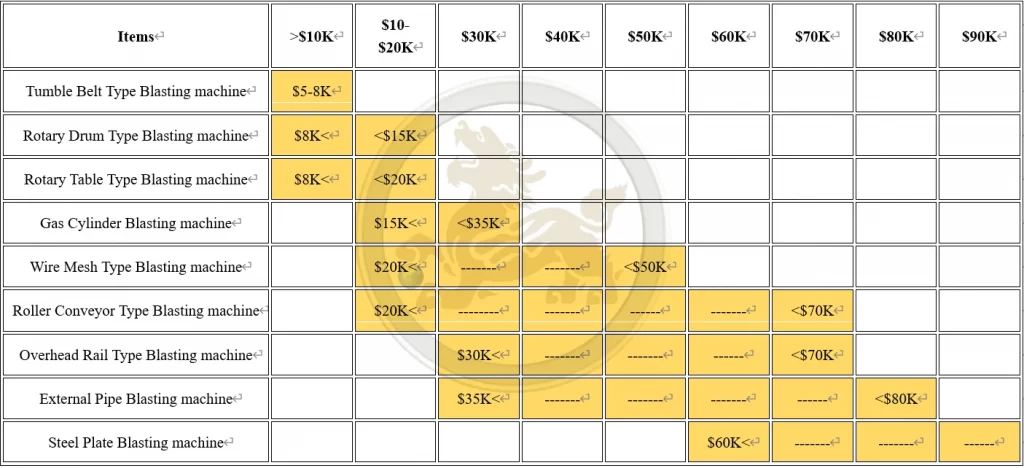

Shot blasting machine for sale:

How to choose of right type of shot blasting machine for sale:

The selection process of the type of shot blasting machines depends on

- The size and shape of the parts to be blasted: whether has dead angles;

- The condition of the surface to be cleaned: the contaminated is rust, sand, rubber, etc.

- The required final surface finish specification: such as Sa 21/2

- The overall required cleaning process quantity per 8 hours.

- The material of parts need be blasted;

Factors that affect the Shot Blasting process and effectiveness:

- The general condition of the metal surface that needs to be cleaned

- What’s the contaminants deposited on the surface that need to be removed (Rust, sand, bur, etc.).

- The metal parts’ material, size and shape (Whether has the dead-angle)

- Hardness, size and material of the shot-abrasive used to treat the surface.

- Velocity, shot projectile capacity and angle of the shot wheel turbine.

- Working Condition of the shot blasting machine.

- The afterward process such like coating, painting etc. If share the same line then the cleaning speed should be consistency.

Main different Parts of the Shot Blast Machine for sale:

The shot blasting machine consists of main different parts:

- Shot Blasting Wheel Turbines

- Shot Blasting Cabinet

- Works Transport Mechanism

- Elevator

- Separator

- Dust Collector

- Electrical Control Cabinet

The following is a detailed description of the function of each part of the machine in the shot blasting process:

Shot Blasting Wheel Turbine: The shot wheel is the heart of every centrifugal shot blasting machine, the shot abrasive projected by the centrifugal shot wheel with a high level of velocity to impact the surface of the works. There are key elements to achieve of optimal cleaning effect: the quantity, angle and capacity;

Shot Blasting Cabinet: Along with the different shapes and sizes of the works, the shot blasting cabinet was built accordingly. The main principle of the shot blasting cabinet is a solid structure in ensuring their strength as well as their durability with closed-circuit to preventing of the abrasive leak;

Work Transport Mechanism: The conveying system depends on the type, size and quality of the work items and the loading/unloading method by manual or automatic. There are a variety of types and designs of the conveying mechanism such as the suspended hook, manual loading of rotary table, automatic loading by rollers, rubber belt for small size works;

Elevator and Screw conveyor: 16Mn material of the parts of the spiral blade, assembled on the end of the screw shaft and convey the shot abrasive to the elevator which is driven by the cycloid pin gear reducer; The screw conveyor gathers the used abrasive into the hopper and elevating to the separator for pure and recovery of the abrasive.

Separator and Abrasive Recovery System: The Separator plays an extremely important role in the abrasive blasting machine. The sieved mixture of abrasives, sand and dust is pushed by the outer spiral of the drum screen and distributed uniformly along the entire length of the separator. Then the abrasives are adjusted by the weight of the separator to flow evenly to the bottom of the separator in a flow curtain state.

Dust Collector: The dust collector is the key function of the shot blasting machine for operators’ protection. Designed as cartridge filter unit in solid steel sheet construction reinforced by profiles & directly mounted on the inlet of the abrasive blasting machine. The cartridges are cleaned automatically and continuously, whereby the filter unit remains operating.

Electrical Control Cabinet: The shot blasting machine’s automatic level depends on the electrical control cabinet, especially of the PLC (Programmable Logic Controller), sensor and safety device;

What material is used for shot blasting?

- Stainless shot steel

- Chilled cast iron

- Casting shot ball

- Glass beads

- Ceramic balls

- Aluminum shot

- Mixed corundum

- Wire cut etc.

Best manufacture of the Shot Blasting Machines:

The Sino wheelAbrator professionals design, technical supporting, manufacture and service shot blasting machine and surface preparation machines and related blasting products for a range of industries, cleaning, derusting, descaling and hardening of surfaces. Improvements can be realized by upgrading to newer technology.

We provide world-class shot blasting machines & granalladora along with new innovative ideas and concepts to eliminate old design problems with shot blasting equipment.

To provide with efficient cleaning and shot-peening system with the ideal shot blasting machine, Quality Spare Centre leading manufacture, trader, supplier, and exporter brings to you a range of metal shot blasting machines and spare parts.