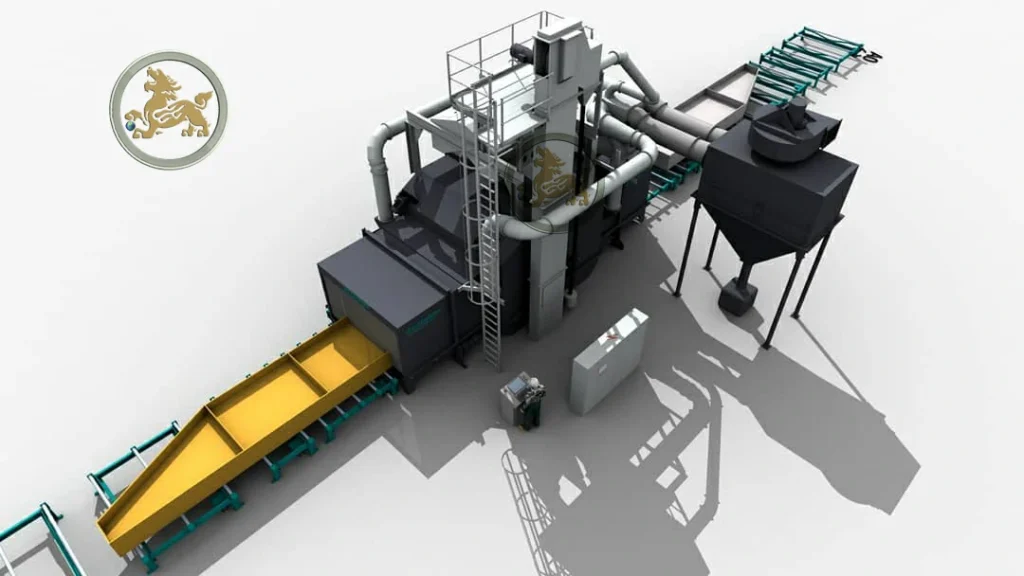

Roller type shot blasting machine

Function of the Roller type Shot Blasting Machines

The roller type shot blasting machine is suitable for surface cleaning of structural parts, profiles, steel pipes, steel plates and steel bars.

High efficiency and low cost.

Automaic Roller-type shot blasting machines are mainly used in construction and other industries. It is used for stress relief and surface rust removal and cleaning of large steel I-beam and H-beam steel structures with higher dimensions. During the cleaning process, the electrically controlled adjustable speed conveying roller conveys the steel structure or steel into the ejection zone of the cleaning machine room, and all sides of its body are hit and rubbed by powerful and dense projectiles from different coordinate positions, making the upper part of the oxide scale, rust layer and its dirt quickly fall off, and the surface of the steel has a certain smooth surface and hardness, which improves the adhesion of the paint film and the steel, improves the internal quality of the steel, and prolongs its service life.

Loading and unloading workpieces on both sides of the cleaning room entrance and exit roller conveyors. The shot-projectiles and rust dust falling on the bottom of the shot blasting room by the sweeping and blowing system, and the scattered abrasive-dust mixture is conveyed to the chamber funnel by the screw recovery screw, and the vertical and horizontal screw conveyors are collected in the lower part of the elevator, and then lifted to the upper part of the elevator. In the hopper of the separated pure projectiles fall into the separator hopper for recycling use by the shot blasting machine. The dust collector is sent to the dust removal system by the exhaust pipe, and the purified air is discharged into the atmosphere. The particulate dust is captured and collected in the dust removal device, and the air discharged into the atmosphere is clean and pollution-free.

Main types of the Roller type Shot Blasting Machines:

1. Roller conveyor type shot blasting machines for beams, profiles, multiple round-bars

The Roller conveyor type shot blasting machine is used for descaling, de-rusting, paint removal, paint preparation, deburring, and general surface preparation prior to welding, cutting, machining, and burning operations, for metal profiles, welded constructions, and sheet metal flat components of all standard widths and lengths, and of any dimension

2. Roller shot blasting machines for sheet-plate

3. Shot blasting system for the optimal tubes, pipes

The pipes shot blasting machines designed to tubes/pipes, round bars, round sections, gas steel bottles, and other cylindrical elements external surfaces treat tubes and cylindrical workpieces (cylinders, tanks, etc.) of various diameters and lengths at various transport speeds in a continuous process.

4. Stone shot blasting machine with netting or conveyor for cement tiles and natural granite

New range of automatic turbine Stone shot blasting machine for the surface superficial treatment (roughening, glazing, distressing, etc.) of marble wall-decorative, slabs of natural marble or agglomerate, granite, as well as cement tiles, interlocking paving, curb-stones, etc. Exposure to the abrasive impact brings out the mineral components in the concrete, tile, and granite, etc., and gives the surface a special appearance, anti-skidding of the road surface or decorative wall of the house.

Applications of the Roller type Shot Blasting Machine:

- Marble & Cement: Stone surface roughness, anti-skid, retexturing, decoration;

- Metal construction works: Cleaning surface for weld, cutting, drilling, etc.

- Pipes: Surface cleaning for painting, coating or drilling, welding, etc.

- Plate: Finishing the sheet surface for painting, coating or cutting, weld, etc.

- Customized-made: Surfacing cleaning of rusting, rubber, sand, etc.

Advantage of the Roller type Shot Blasting Machine:

- Compact steel structure, high blasting efficiency, good cleaning quality, safe and reliable work, stable operation process

- The cleaning blast room mounted with high chromium steel guard plate, which is abrasion-resistant and impact-resistant, and has good strength

- Conveying by VFD rollers, It can pass heavy and super long workpieces with avariable speed

- Level 3 dust removal (cartridge filter), large suction volume, clean dust filtration, and air emission in line with environmental protection standards

Best manufacture of the Roller type Shot Blasting Machines:

The Sino wheelAbrator professionals design, technical supporting, manufactures and services shot blasting machine and surface preparation machines and related blasting products for a range of industries, cleaning, derusting, descaling and hardening of surfaces. Improvements can be realized by upgrading to newer technology.

We provide world-class shot blasting machines & granalladora along with new innovative ideas and concepts to eliminate old design problems with shot blasting equipment.