Surface preparation standard of abrasive cleaning: SSPC/NACE & ISO 8501 (Sa 2.5)

Table of Contents

What is SA 2.5 blasting in surface preparation standards?

The two dominant abrasive blasting cleaning surface preparation standards of the ISO 8501 (Sa) and the SSPC/NACE joint standards, are very difficult to compare, because they widely recognize share the same levels of cleanliness of the surface preparation grade.

The purpose of surface preparations standards exist to maximize coating/painting lifespan and minimize cleaning costs.

Surface preparation standards grade of ISO 8501: What is Sa 2.5 in Shot blasting:

The ISO 8501 was published by the ISO (International Standards Organization) in 1988, combined the standard of the 1967 Swedish Standard: SIS 055900 and the German: DIN 55928. ISO 8501 is a pictorial standard showing the appearance of different rust grades at various levels of cleanliness, it also contains text descriptions of the cleanliness levels.

The China national standard GB8923-88 “Steel surface modification grade and rust removal grade before painting” divides the rust removal grade of shot blasting machine into four grades, which are represented by the letter “Sa”.

- Sa 1: Mild spray (Sandblasting) or projectile (shot blasting) rust removal. There is no visible grease or dirt on the surface of the steel, and there is no loose oxide scale, rust, paint coating and other attachments.

- Sa 2: thoroughly spray (Sandblasting) or projectile (shot blasting) to remove rust. There should be no visible grease, dirt, oxide scale, rust and other attachments on the steel surface, and the residues should be firmly attached. The projectile dents formed after shot blasting are evenly arranged on the steel surface, and the anti-slip coefficient reaches 0.35~45

- Sa 2.5 / 21/2: very thorough spray (Sandblasting) or projectile (shot blasting) to remove rust of Sa 2.5. There should be no visible grease, dirt, oxide scale, rust, paint coating and other attachments on the surface of the steel, and any remaining traces should only be light spots or strips. The projectile dents formed after shot blasting are evenly arranged on the steel surface, and the anti-slip coefficient reaches 0.45~5

- Sa 3: makes the steel surface clean by spray (Sandblasting) or projectile (shot blasting) to remove rust. There should be no visible grease, dirt, oxide scale, rust, paint and other attachments on the steel surface, and the surface should show a uniform metallic luster.

Surface preparation standards grade of SSPC/NACE joint:

In North America, the original surface preparation standard was issued by an architectural group in the 1960s by steelworkers in Pittsburgh. The SSPC (Society for Steel Painting Structures) formed the SSPC standards are text descriptions, not pictorial, although they are accompanied by visual guides (VIS) with photo references. In 2000, SSPC and NACE issued joint standards in anticipation of a merger between the organizations and SSPC/NACE numbers them in reverse order, by increasing surface cleanliness.

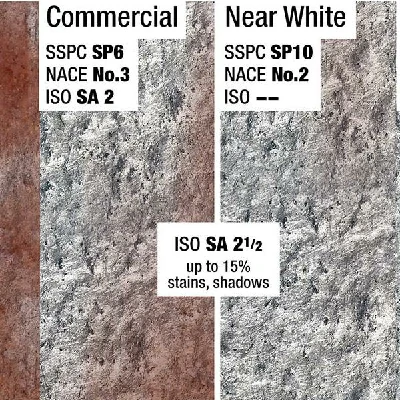

What is the ISO standard of Sa 2.5 roughly match with the standards grade of SSPC/NACE joint?

ISO adapted the most common standard as Sa 2 1/2, Very Thorough Blasting Cleaning, while SSPC used as SP 10 Near White. The two versions were not equal: Sa 2.5 permitted stains, streaks and shadows from rust, mill scale and coatings to remain on up to 15% of the surface, whereas SP 10 allowed for only 5%.