No.1 of completely shot-blasting machine guideline: What is the shot blasting machines? What is shot blasting machine used for?

Table of Contents

Functions of the Shot blast machines:

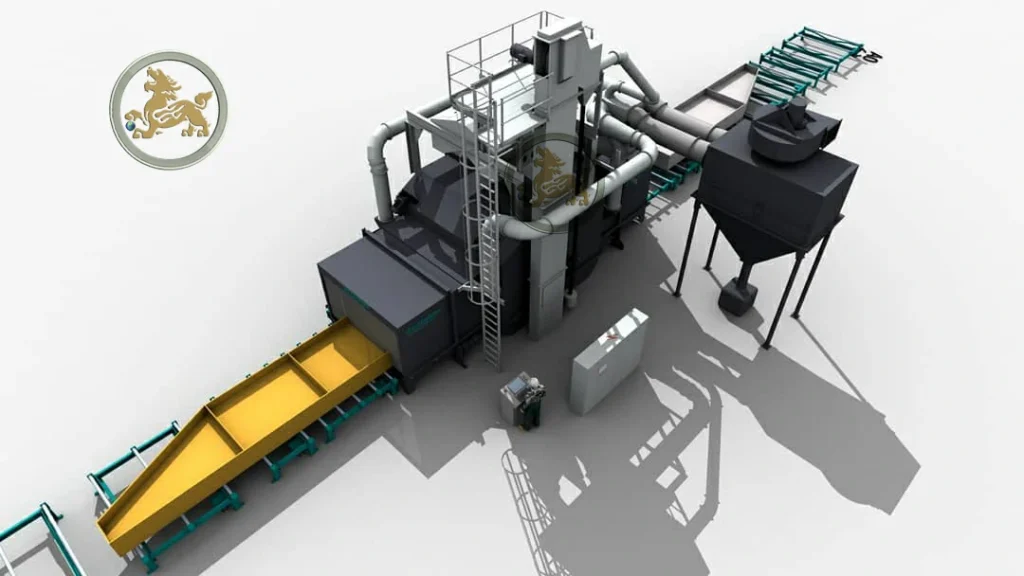

Sino-Abrator develops increasingly specialized in shot blast machihnes, sand blasting machines manufacture, efficient and performing cutting-edge technologies of the turbine-wheel shot blast machine is widely used for treatment of mainly metallic and stone surfaces.

The shot-blast purpose includes of the de-rusting, descaling, de-sanding, or deburring of the work pieces. Other uses are improving of anti-fatigue, hardening of surfaces for longer lifespan (shot-peening), finish blasting of sensitive parts and roughening of surfaces ready for coating or painting.

Surface cleaning

Shot blast equipment is initially used in the foundry industry to remove sticky sand, oxide scale from the surface of steel and iron castings. This is also an indispensable preparation process before the quality inspection of the casting.

Workpiece strengthening

According to modern metal strength theory, the main way to improve metal strength is to increase the dislocation stress inside the metal.

Models of the Shot Blast Machines:

What is the difference between shot blasting and sand blasting?

Blasting technology is used in almost all industries of metal. Shot blasting and sandblasting are both a kind of surface cold treatment cleaning technology. It is a necessary process to use steel grit or steel shot to remove surface stains and rust and verify the integrity of the product surface. Compared with other surface treatment technologies, its surface treatment ability and environmental friendliness are faster and more effective, which is the first choice;

The difference between shot blasting or sandblasting:

Drive mode:

Shot blasting uses the centrifugal rotating turbine blades of the blasting head to throw high-speed (about 70-90 m/s) steel medium (high-speed beads of steel, copper, aluminum or other materials as the shot blasting medium), and project it onto the upper surface of the shot blasting machine. Deburring, sanding, cleaning or strengthening the surface of castings at a certain angle, or removing rust, paint or other coatings, etc.;

Sand blasting medium is pneumatically accelerated by compressed air instead of a centrifugal turbine. Sand or other abrasives are driven by compressed air through a tube, allowing the user to control the spray direction, and finally sprayed onto the part through a nozzle.

Different blasting materials:

Shot blasting: because of the large centrifugal forcethe of shot wheel, metal shot abrasive is used in most cases, and the separator is used for recycling;

Sand blasting uses compressed air, either metal shots or sand such as Glass beads, but Glass beads are not recyclable and disposable.

The effect on the environment:

Shot blasting has a dust collector, it greatly reduces the impact on the environment and basically achieves a dust-free treatment;

Large sand blasting equipment is equipped with a dust collector, and small sand blasting equipment works in the open air, which has a certain impact on the environment;

Differences in processing workpieces:

Shot blasting is basically the cleaning of metal surfaces, and can also be used for stones, concrete, etc.;

Sand blasting can be used for metal, plastic, glass and other fragile products;

What is the Difference Between Shot Blasting and Shot Peening?

What is the difference between shot blasting machine and shot peening machine?

Shot blasting machine is primarily a surface finishing process. To modify the surface of parts to smooth rough surfaces, reshape surfaces, or remove surface contaminants. That is typically used to prepare the surface for subsequent operations (such as painting, coating, etc.) to improve adhesion and smoothness.

The biggest difference between shot peening machines is “peening”, which is improve the material properties of the surface to increasing the compressive stress.

Applications of the Shot Blast Machines:

- Foundry and Forge industries: the shot blasting equipment mainly for the de-sanding, deburring of refreshing surface, detect of the defect of casting parts. Tumble blasting machine, Rotary-table blasting machine, rolling drum shot blast machine;

- Steel plate industry: The steel plate will have some burrs, which will affect the appearance of the steel, or the rust expose after the rain, can choose of the roller type steel plate pretreatment line.

- For beams, profiles: large size, high quality, high corrosion-resistant flat steel and large angle steel with unequal sides and thickness, use the roller type shot blast machine to ensure no longer have dead-angles.

- Hardware industry: In the hardware industry, there are a large number of parts and many types. Most parts need to clean, smooth, and flat on the surface. Generally, hook type or crawler shot blast machines.

- Automobile industry: Many parts in the automotive industry need derust and polish. The shot blasting machine can achieve rust removal and polishing without affecting the shape and material strength. The shot blast machine and sandblasting room is a welcome method.

- Bearing and mold industry: The bearing and mold industry has high surface requirements to remove various burrs, impurities, etc.; recommend the rotary table shot blast machine.

- Valve factory: All kinds of valves are basically castings, suitable for crawler shot blast machine, which can clean 600-1000kg at one time.

- LPG gas tank: use the hook-through type and the special steel cylinder shot blast machine, which has high efficiency and a good cleaning effect.

Advantages of the Shot Blast Machines:

- Shot Blast Machine is automatic process within manual assist, which is save working time and reuseable shot-abrasive that is economics method, and affordable cleaning for surface finishing;

- The surface cleans with smoothens and homogeneity finishing, without any damage to the surface.

- Environment friendly, without any pollution compared to sandblasting.

- Prepares a surface for coating or painting preparetion applications effectively.

- The flexibility of using various types of shot abrasives that can be used in the shot blast machine according to the surfaces grades and different material that need to be cleaned (such as glass beads, steel shots, steel grit, etc.) makes shot blast is the most preferred cleaning or surface finishing method.

Efficient of the Shot Blasting Machines:

Cement surface: work efficiency: 200-400 square meters/hour

Working on steel plates: steel quality grades SA 2,5 to SA3 Speed: SA2,5 about 4m/min; Speed: SA3 about 3m/min, processing area per hour: SA2,5, about 75-100 square meters /Hour

What material is used for shot blasting?

- Stainless shot steel

- Chilled cast iron

- Casting shot ball

- Glass beads

- Ceramic balls

- Aluminum shot

- Mixed corundum

- Wire cut etc.

Factors that affect the Shot Blasting process and effectiveness:

- General condition of the metal surface that needs to be cleaned

- What’s the contaminants deposited on the surface that need to be removed (Rust, sand, bur, etc.).

- The metal parts’ material, size and shape (Whether has the dead-angle)

- Hardness, size and material of the shot-abrasive used to treat the surface.

- Velocity, shot projectile capacity and angle of the shot wheel turbine.

- Working Condition of the shot blasting machine.

- The afterward process such like coating, painting etc. If share the same line then the cleaning speed should be consistency.

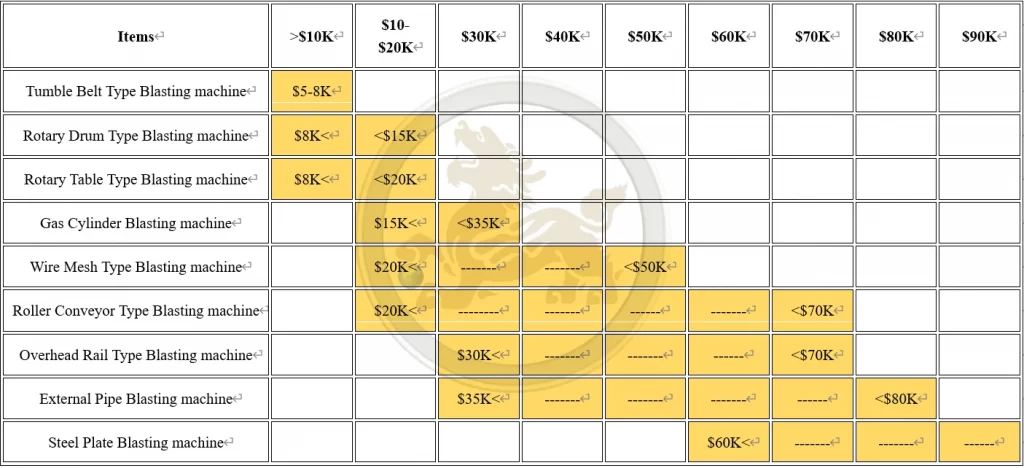

How much is a shot blaster?

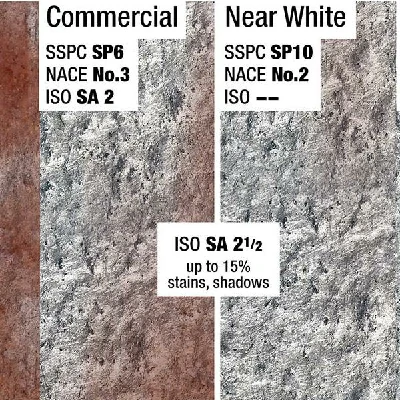

surface preparation standards grade: What is Sa 2.5 in Shot blasting:

The national standard GB8923-88 “Steel surface modification grade and rust removal grade before painting” divides the rust removal grade of shot blasting machine into four grades, which are represented by the letter “Sa”.

- Sa 1: Mild spray (Sandblasting) or projectile (shot blasting) rust removal. There is no visible grease or dirt on the surface of the steel, and there is no loose oxide scale, rust, paint coating and other attachments.

- Sa 2: thoroughly spray (Sandblasting) or projectile (shot blasting) to remove rust. There should be no visible grease, dirt, oxide scale, rust and other attachments on the steel surface, and the residues should be firmly attached. The projectile dents formed after shot blasting are evenly arranged on the steel surface, and the anti-slip coefficient reaches 0.35~45;

- Sa 21/2: very thorough spray (Sandblasting) or projectile (shot blasting) to remove rust of Sa 2.5. There should be no visible grease, dirt, oxide scale, rust, paint coating and other attachments on the surface of the steel, and any remaining traces should only be light spots or strips. The projectile dents formed after shot blasting are evenly arranged on the steel surface, and the anti-slip coefficient reaches 0.45~5

- Sa 3: makes the steel surface clean by spray (Sandblasting) or projectile (shot blasting) to remove rust. There should be no visible grease, dirt, oxide scale, rust, paint and other attachments on the steel surface, and the surface should show a uniform metallic luster.

Main structure of the Shot Blasting Machines:

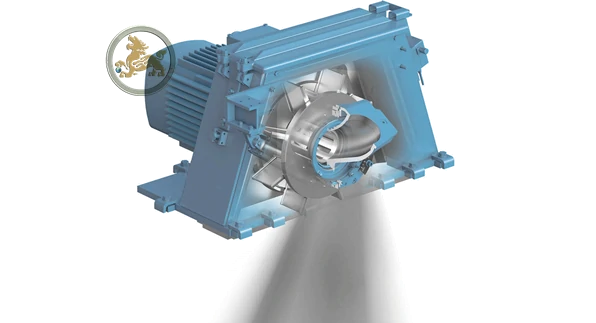

1. Shot wheel turbines:

- The shot wheel turbines are essential to the shot blasting machine.

- The performance of the shot blasting device depends on the quality, quantity, speed and direction angle of the shot-projectile; the last three factors depend entirely on the selection, design, installation and correct operation of the shot blasting equipment.

- More information…

2. Blasting room structure:

- 10mm thickness primary heavy-duty steel plate which mounted on complex and strong structural steel framework;

- The direct shot abrasive projectile area mounted with 12mm thickness wearing-resistance anti-shock rolled ZGMn13;

- Inside of the door is fully lined with rubber liner, to prevent the escape of abrasive from cabinet.

3. Conveyor transport system:

- Hook type blasting equipment: with one or multi pieces of the hooks, manual load suit for the small, medium and large size of workpieces

- Roller type shot blasting equipment: Rollers in the blasting cabinet are protected by special alloy jacket with lifetime over 4,000 hours. Conveyor system is driven by motors with inverter to control of the cleaning speed;

- Tumble type shot blasting equipment: with endless rotate rubber belt, the workpieces tumbling inside of the blasting cabinet;

- Rotary table and Rolling drum type shot blasting machine: the table and drum made of the wearing-resistance casting liners with longer lifespan;

4. Shot abrasive recycle system:

- Screw conveyor: 16Mn material of the parts of the spiral blade, assembled on the end of the screw shaft and convey the shot abrasive to the elevatorwhich driven by the cycloid pin gear reducer;

- Elevator: The abrasives are lifted to the bottom of the elevator, and finally dropped by centrifugal gravity, and the abrasives are fed for separator;

- Separator: The sieved mixture of abrasives, sand and dust is pushed by the outer spiral of the drum screen and distributed uniformly along the entire length of the separator. Then the abrasives are adjusted by the weight of the separator to flow evenly to the bottom of the separator in a flow curtain state.

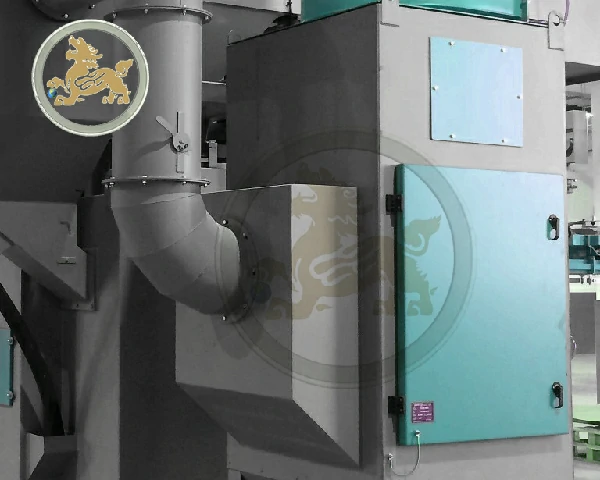

5. Dust collector:

- Designed as cartridge filter unit in solid steel sheet construction reinforced by profiles & directly mounted on inlet of the abrasive blasting machine. The cartridges are cleaned automatically and continuously, whereby the filter unit remains operating.

6. Electrical control cabinet:

- PLC (Programmable Logic Controller): For the central automatic control of the machine via a PLC type Siemens.

- Sensor: With Automatic Star-Delta switching for all motors exceeding power with all the contactors and protection for the direct switching of all other motors installed as well as ammeters for controlling and adjusting the turbines.

- Safety: Various safety features are inbuilt in the system like blast wheel motor will not operate if door is opened, it is entails by contactors, relays, push buttons, main isolation switch, safety limit switch, emergency switch, grounding system, inbuilt single-phase prevention, over-load & short circuit protection, HRC fuses, indicating lamps etc.

Shot Blasting Machines maintenance:

Check the daily work diary, confirm the working status of the shot blasting machine before every shift, make sure that the work is orderly, the responsibilities are clear, the responsibilities are assigned to specific people, and the records can be checked;

After the daily work is completed, the steel abrasive scattered on the ground shall be cleaned up in time, and the power and the air source shall be cut off;

Before each maintenance, make sure cut-off the power, the sign of “Maintenance states” is obvious and clear; if you need someone to inspect and repair inside the shot blasting machine, set up a notice board in a conspicuous position, and the equipment must be in a safe control state and be looked after by someone;

Daily/Weekly/Monthly/Quarterly/Annual maintenance of shot blasting machine:

More information…..

Best manufacture of the Shot Blasting Machines:

The Sino wheelAbrator professionals design, technical supporting, manufactures and services shot blasting machine and surface preparation machines and related blasting products for a range of industries, cleaning, derusting, descaling and hardening of surfaces. Improvements can be realized by upgrading to newer technology.

We provide world-class shot blasting machines & granalladora along with new innovative ideas and concepts to eliminate old design problems with shot blasting equipment.