Manual sand-blasting room

Manual Sand blasting room systems are designed for manual or automatic compressed-air projectile toward workpieces via blasting nozzles by shot abrasive. Customized-made blasting room by specific size and material requirements, designed for blasting work-pieces of large dimensions, weights, and complex geometries shape such as welded engineering pieces, foundry castings, forgings, railway wagons, die-casting, containers, etc.; With multi-functional of cleaning prior for the coating or paint line.

Sand blasting room systems are constructed from modular steel panels or self-supporting panels featuring polyurethane resin insulation. Walls are lined with special abrasion-resistant reinforced rubber. The floor is made from metal grating system of screw conveyors or scraping conveyors applied to the whole shot blasting chamber for automatic shot-abrasive recovery system installed underneath.

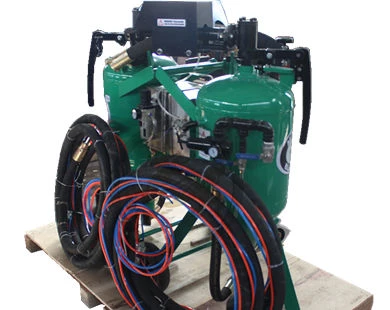

The Sand blasting systems are finished off with pedestrian access doors, transporting system by track or hanger system, lighting system, platforms with fixed or moving walls for sand-blasting parts higher up, an extraction and ventilation system, self-cleaning dry-type cartridge filter, and manual or automatic sandblaster.

The sand blasting room is universal use of any kind of shape, especially of the un-standard shape and large size, such as the railway wagon etc.

Feature of sand blasting machine:

- Manual operation to ensure precision;

- Perfect for smooth surface finishing;

- Versatile for small to medium-sized products such as casting, forging, welding, etc.

- No pollution for environmental protection;

Applications of sand blasting system:

- Foundry: De-sanding & deburring of casting finishing; Descaling, removing rust and oxides; (ductile casting, sand casting, nodular cast iron, gray iron casting.)

- Forge: Deburring and homogenizing casting surface; Elimination of temper remains;

- Aluminum die-casting: Refreshing the diecasting surface;

- Pipes: Surface cleaning for painting, coating or drilling, welding, etc.

- Shot-Peening: Increasing the stressed & fatigue strength of components;

- Customized-made: Surfacing cleaning of rusting, rubber, sand etc.