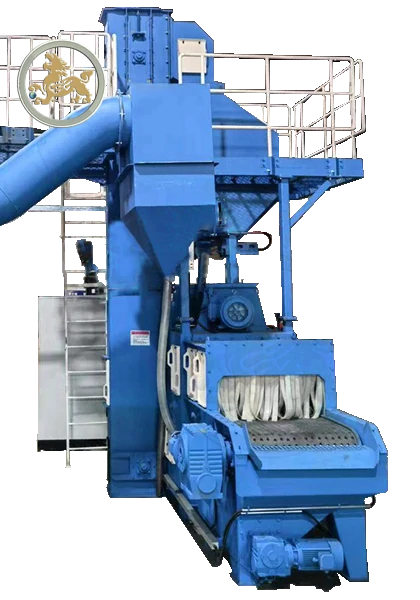

Continuous Rubber Sheet Shot Blasting Machine

Rubber Sheet Shot Blasting Machine / Rubber belt continuous shot blasting machine, with rotate conveyor rubber belts supported by inside rollers, is designed to allow priority is top and side surfaces of small and medium-sized non-collision items, in intermittent, loaded by manual or automatically.

Rubber Sheet Sand Blasting Machine, with a high-resistance rubber belt, which is made from an extraordinary blend crafted from natural and synthetic rubber complex; which composition grants it exceptional properties like impervious to the ravages of wear and tear, the forceful impact of substantial particles, and the scourge of abrasions, extraordinary degree of elasticity and impressive resistance to a variety of gentle chemicals, acids, and alkalis, further enhancing its versatility and durability.

Rubber Sheet Shot Blasting Machinery, with shot turbines installed on the top only, is a good option for mass-produced parts, which can not be tumbled and will perfectly match the casting and mold de-sanding, descaling, de-flashing, deburring, and shot peening.

Features of Shot Blasting Machine:

- Continuous cleaning and saving labor costs;

- Compact design structure, no foundation required, low noise;

- Perfect of finishing consistency of surface cleaning;

- Only for top and side surface and afraid collision during blasting;

- No pollution for the environmental protection;

Applications of Shot Blasting Machine:

- Wheel rims: Surface blasting finishing uniform.

- Aluminum die-casting: Surface blasting finishing uniform.

- Marble, Blocks, Bricks, Tiles, Kerbstones, Slabs & Cement: Stone surface roughness, anti-skid, retexturing, decoration;

- Customized-made: Surfacing De-sanding, stripping and preparing for cutting, welding, drilling or pior preparing of painting etc.

Characteristics of Rubber-Sheet Shot Blasting Machine:

High efficient of Shot wheel Turbines:

- Compact shell structure, longer lifespan of blades, lower maintenance;

- Upgraded wearing-resistance with low working noise & vibration;

- High-speed blasting capacity with more recycle abrasive using;

- Optimal blasting angle, velocity and energy-saving;

- 360 degrees of coverage, no dead-angle left;

- VFD (Variable Frequent Drive) for motor to adjust of the shot projectile capacity;

- More information……

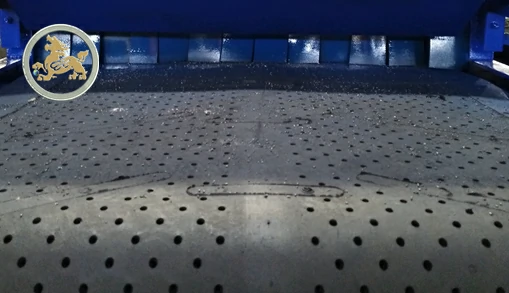

Rubber sheet system:

- The continuous rubber belt or steel apron, very easy of loading and operation;

- Wearing-resistance rubber belt suits for the light-duty;

- The workpieces range from smaller size to medium-large size;

- VFD (Variable Frequent Drive) for the turntable motor to adjust the rotary speed to achieve of best cleaning;

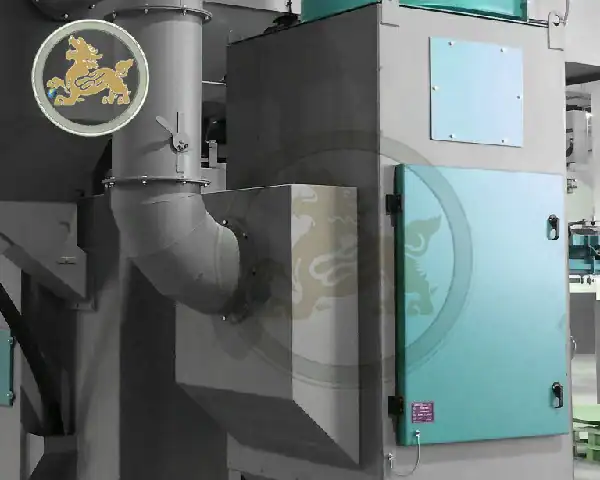

Elevator & Screw Conveyor:

- Abrasive collect and transport to elevator via screw conveyor;

- The elevator lifts the abrasive to the separator;

- Bucket made of foundry casting;

- Tension device prevents belt slide;

Separator:

- Separator adopts DISA & Pangborn technology;

- 3-class of separating abrasive;

- Efficient reach of 99.5%

- Abrasive hopper for abrasive accumulate;

- Electro-Magnetic valve control of abrasive flow;

Dust Collecting system:

- Cartridge type of dust collector;

- The efficient reach of 99.9%;

- Very easy of replacing of cartridge filters;

- Silencer to minimize of noise;

- Maintenance platform;

Electrical Control system:

- PLC (programmable logic controller) for an automated process;

- Safety interlock for operation;

- HMI (human-machine interface) control panel;

- IP65 protection for the control cabinet;

- Air conditioning;

- 230V/3ph/60Hz or 380V/3ph/50Hz cycle electrics;

- PLC (Programmable Logic Controller) for automatic process;

- HMI (Human-Machine-Interface) for touch screen control;

- Variable blasting speed in continuous flow blasting machines;

- Dust collector with sound silencer;

- Pneumatic unload flip gates;